L'Edifice - Reproduction

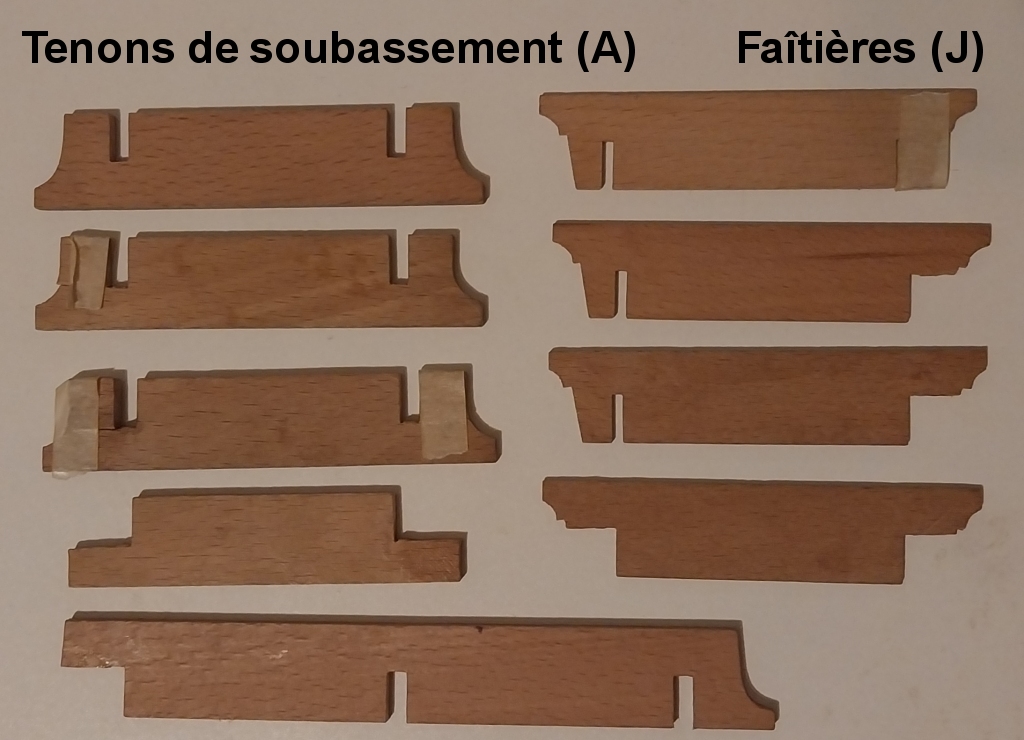

Encouraged by fellow L'Edifice enthousiasts, it's time to re-create some wooden parts. Basically half of the 'A - Tenons de soubassement' are missing and/or broken, same issue with the 'J- Faîtières'... Also want those M4/M5 stairs and still missing some panels...

It's time for replacement parts!

The system

The basic building system consists of horizontal trusses (A - Tenons de soubassements) and vertical pillars & columns (B - Piliers et Colonnes). Floor tiles (C) could be added inbetween the pillars, on top of the trusses. The pillars are having grooves, so nicely decorated panels (D) could be inserted. In this way a structure could be build.

The trusses are used for both ground level and (placed upsidedown) for all floor levels above. At ground level the longer pillars (B1's) sticking straight into the trusses. Then a layer of trusses could be build. For all the layers above, shorter pillars (B2's) are used.

So the ground level uses floor tiles (C) and then wall panels, at floor levels 'gutters' (E) are used instead, creating a very nice appearance.

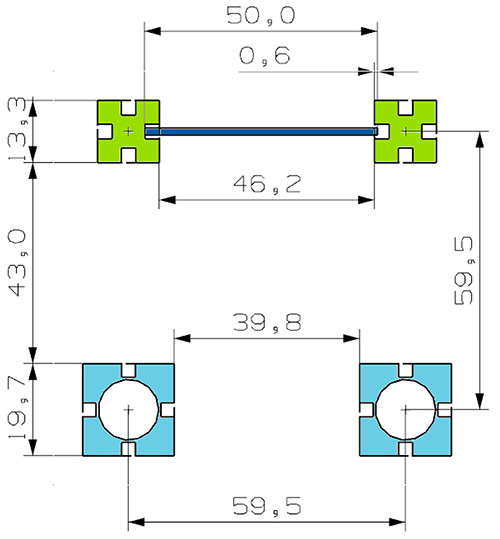

Dimensions

Building the same construction from different boxes, it appears that some wooden parts fits better then others and even the pitches between columns varies a bit, using the original pieces.

Right: Set 2 (±1922) panels & Set-3 (1927): wood.

Both examples are coming from the same 'Gothic Flamboyant Casltes' period (1922-1930), with simular front picture. It seems to me, that the earlier boxes having a thighter fit.

Nominal distances...

The nominal pitch distance between columns: 59.0 to 59.5 mm.

Because columns are wider then pillars, also different C & K panels exists.

Steamed beech wood

L'Edifice is build from steamed beech. In picture on top of page, on the left building, I did use the new none-steamed Tenons (A).

There is an obvious contrast shown, between the Tenons (A) & Pillars (B).

The right building is created from a younger Set-3 (1927) and here also lighter wood is used, but still darker then the new Tenons.

It's possible to 'darken' the wood a bit, using 'black tea'. But thinking about it, the wood produced around 1920 would have been lighter too.

A. Tenons de soubassement

Let's start with the horizontal trusses. Half the trusses having one or more broken notches. This is a common issue, looking to various online pictures.

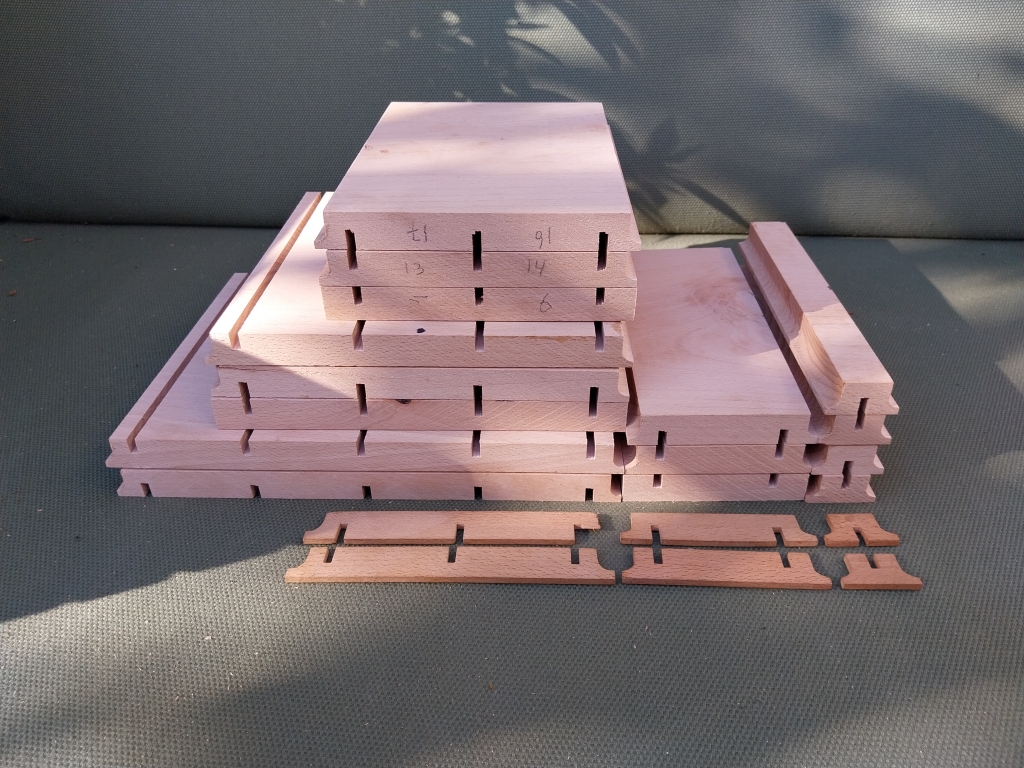

Production

How did Mercant created these parts?

My guess: They would be using a big circular saw and some profile cutters, starting with a beam of steamed beach wood. So let's try that.

- Start trimming the beam to the right height.

- Saw repetivialy parallel grooves over full length.

- Cut the beam in smaller blocks for certain lengths.

- Cut the contours at both ends.

This will make the difference between a A2 & A2-bis. - Finally slice the wooden blocks in thin parts.

Finally ended up with about 210 parts. From those, about ~15 parts were trash.

Comparison to other boxes:

| Truss: | DIY | No. 1 | No. 4 | No. 6 |

| A1 | 21 | 4 | 10 | 24 |

| A1-bis | 20 | 3 | 10 | 14 |

| A2 | 22 | 5 | 10 | 20 |

| A2-bis | 24 | 5 | 12 | 16 |

| A3 | 21 | 4 | 14 | 15 |

| A3-bis | 20 | 4 | 13 | 14 |

| A4 | 21 | - | 6 | 25 |

| A4-bis | 20 | - | 11 | 19 |

| A5 | 20 | - | 6 | 12 |

| A5-bis | 20 | - | 3 | 14 |

| ... | - | - | +3 more | +21 more |

| Sum: | 209 | 25 | 98 | 194 |

So this amount of wooden parts is getting close to Set No. 6.

B. Piliers et Colonnes

Since my Set No. 4 consists mostly out of cardboard parts, it might even be fun creating all missing wooden parts.

Let's start with the pillars: B1, B2, B3 & B11.

Production

- Saw square strokes out of beech.

- Cut the 3mm grooves on all 4 sides.

- Cut beams in right lengths.

- Cut the 4mm grooves on top & bottom.

Everything is done with a circle saw, with some light steamed wood.

That was a bit time consuming. But at least enough wood for set 4.

J. Faîtières

These Faîtières could be created simular like the Tenons de soubassement (A):

I knew already, the grooves of the tenons are wider then needed for these Faîtières, but just wanted the experience of cutting these thinner parts.

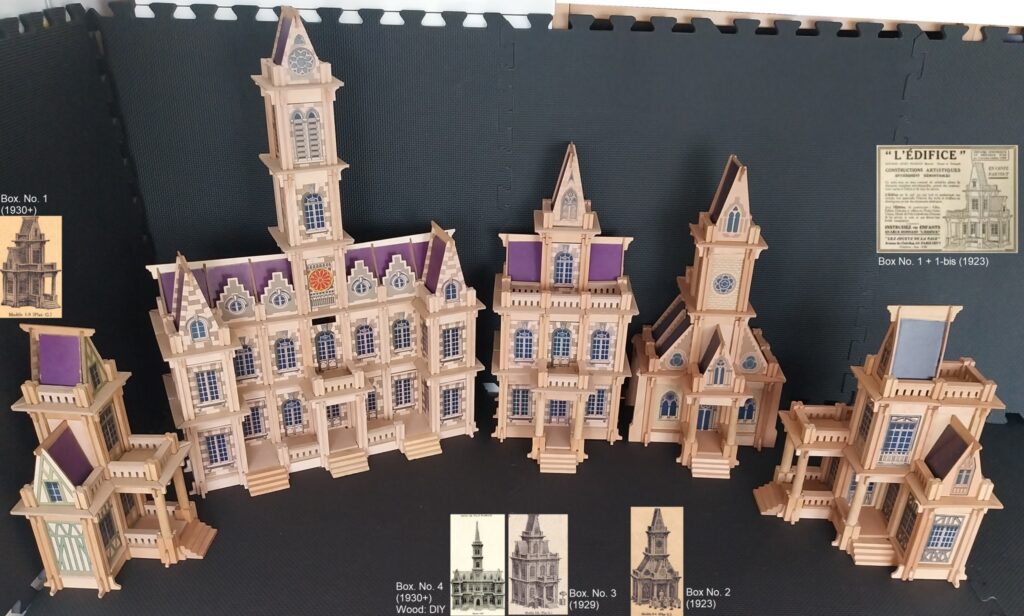

Time to test & build

Building with different boxes from different periods.

From right to left:

- Set 1923: Box 1 + 1bis combined.

Model:

1921 advertisement, example for box 2.

Manual 1922 - Model box No. 2.

Manual 1926 - Model 2-13, box 2. - Set 1923: Box 2:

Model:

Manual 1923 - Model box No. 2

Manual 1926 - Model 3-4. - Set 1929: Box 3.

Model:

Manual 1926 - Model 3-6. - Set 1930+: Box 4.

Model:

Contest Lepin 1920, all wooden panels.

Manual 1922 - Hotel De Ville Flamand (No. 56)

Manual 1926 - example for box 4.

Manual 1928 - Model 4-13

→ This model contains all DIY wood, as described above. - Set 1930+: Box 1.

Model: Normandic house

Manual 1922 - Model box No. 1.

Manual 1926 - Model 1-9.

For set 4, the truss A6/A6-bis is missing, wich explains the hole in the middle of the building, on the 1st floor. In this case 2x A4's is used.

This also explains the need for so many different sized 'tenons'...

It's also clear, that the fresh new wood is lighter then they other wood used. Maybe it did look like this, when Mercant was producing these parts?

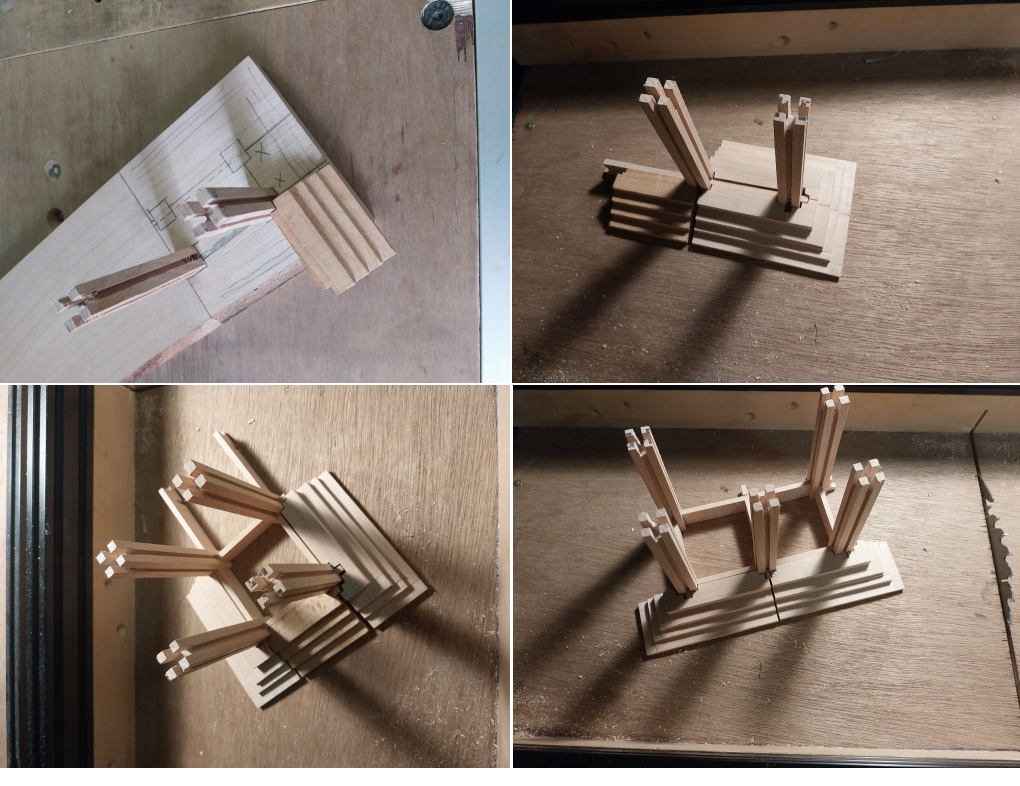

M. Escaliers

Always liked those M4, M5 & M6 staircases, for making a great entrance. Since it's impossible to find original parts, let's give it try and build my own.

With only a circlesaw and a M1 stair case for reference, let's do this.

Starting with a small drawing on top, needed 2 hours to cut those M4 & M5 stair cases. Now I do understand, why these are one of the most expensive pieces on the price list, around 1925: 2.7 French franc per piece. Even more costly then 12x pillars B1.

D. Panneaux

Then I'm also looking for more (fortress) panels...

So how could these be created/printed best?

Any thoughts how to do? Let me know!

This was a fun project, working with beech, upgraded some tooling in the garage. And on top of that, finally possible to build with set No. 4 too.

If you need parts too and don't want to make them yourselves, get in contact.

Click here, for a short intro about L'Edifice.